How To Select The Correct Refrigerant Control Valve For Your Variable Displacement Compressor

What is A Variable Displacement Compressor?

Your wife comes home and says “Honey, the AC in my car isn’t working” and you reply “OK dear, I’ll check it out”. You then get in the car, drive down the road and ice cubes are spewing from the vents. Puzzled, you return home and proceed to tell her she probably had the switch in the wrong position and that all is well….until it does it again and this time she confirms that everything is turned on and the AC system begins to routinely operate intermittently or, marginally, at best.

The system takes a long time to get cold, quits working for no rhyme or reason and then starts working again or just doesn’t get quite as cold as it should be. Puzzled, you take the car to the dealer and he tells you your compressor is weak and needs to be changed. He then hands you a $1500 - $2000 quote. With your heart sinking rapidly while your blood pressure is raising you go online and learn that this is a common problem with Volkswagen AC systems and often times there is an inexpensive fix for it.

Realize that while these can be symptoms of many things from a bad fan to a loose wire, if you own a Volkswagen, odds are overwhelming that the variable displacement mechanism in your compressor is malfunctioning.

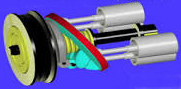

A variable displacement compressor is one that varies the stroke of the pistons by changing the angle of the wobble plate. It does so by utilizing what is referred to as a REFRIGERANT CONTROL VALVE or an RCV. An overly simple explanation of how they work is that they bleed pressure internally from the high side to the low side and use that pressure to vary the angle of the wobble plate.

In the above image the wobble plate is pictured in red. It is easy to see how by varying the angle of that plate we can vary the stroke of the piston which in turn raises or lowers the displacement when under load. The steeper the angle the longer the stroke of the piston, the less steep the angle, the shorter the stroke of the piston, hence the compressor only pumps as much as is necessary.

These valves come in two varieties: Mechanical and Electronic.

The electronic valve accomplishes the same task, albeit a little differently. Systems utilizing this type of valve also have pressure and temperature sensors which send data to the vehicles computer. The computer processes this information and controls the valves duty cycle which in turn controls housing pressure and piston stroke. This is accomplished using “PWM” or Pulse Width Modulation. In layman’s terms, the valve is controlled with a pulse rather than a continuous voltage. This causes the valve to cycle on and off often within a short time span.

So How Do I Know Which Variety I Have?

If you’ve read this far it is probably because you have learned that your vehicle has a variable displacement compressor and you want to learn how to identify it and determine if it is in fact the cause of your problem.

There are two varieties of control valve: Mechanical and Electronic.

Mechanical control valves can be mounted either internally or externally. External valves are mounted on the rear head of the compressor and are held in place with a snap ring. They can often be removed without removing the compressor from the car. Simply remove the Freon, remove the snap ring and swap out the valve.

Do not attempt to remove the snap ring until you are certain all of the Freon is removed from the system. Failure to do this will cause it to shoot out of the compressor like a bullet and possibly cause serious bodily harm.

Some valves are mounted internally, most notably the Sanden SD7V and SD6V series popular on late 1990’s to early 2000’s vintage Volkswagens. These require removal of the rear compressor head to access the valve.

Electronic control valves are always mounted externally and are usually used in conjunction with a “direct drive” compressor (one which has no electromagnet in the clutch assembly and is continuously engaged). They can be secured in place with either a bolt or a snap ring and may be removed using the same process described above for external mechanical valve removal. They are usually mounted on the side of the rear compressor head and always have a wire running to it. If there is no wire coming from behind the pulley and one running to the back of the compressor, you have a direct drive compressor with an electronic control valve. Trace the wire and you will find the valve.

Once again do not attempt to remove the snap ring or bolt until you are certain all of the Freon is removed from the system. Failure to do this will cause it to shoot out of the compressor like a bullet and possibly cause serious bodily harm.

Diagnosis

Diagnosing a problem in a system using a variable displacement compressor is a bit more complex than in a system with a fixed displacement compressor and it is not something the average DIY’er will have the equipment to do. Add in the electronic component and it becomes even more complex but do not despair. There are ways around the expensive tools and equipment that are reasonably accurate. Of course realize that even with the fancy tools, changing a control valve is always a bit of a crap shoot, but it is possible to skew the odds overwhelmingly in your favor.

If your air conditioner works erratically or it blows cold but not quite cold enough you may have a control valve issue. Realize however, that there are numerous other things that could cause similar symptoms, ranging from bad fans, a broken wire or a computer sending no signal to the valve. While it has been our experience that most of the time these symptoms are indicative of a bad valve, we want our customers to realize that there are other possibilities and that changing the valve is never a 100% sure fix.

Identifying Your Valve

The “lookups” for mechanical control valves are reasonably accurate. Often times you can purchase the correct valve by simply knowing the type and model of compressor you have. A few require removal of the valve and comparison to an image or a physical matchup.

Unfortunately, electronic control valves do not have reliable “lookups”. To further compound the issue, some vehicle manufacturers, most notably Volkswagen, are not consistent with their applications. For example, you can have two identical vehicles – same year, model and engine – and have multiple compressors from several manufacturers ALL WITH THE SAME FOOTPRINT. This means that your Denso brand compressor can replace your Sanden compressor but they use different electronic control valves. This is why we encourage our customers to call us and / or email us images if they are not sure of what they are ordering.

Electronic control valves are always externally mounted and can be secured in place with either a bolt or a snap ring. However, they are not quite as easy to identify. To assist you in identifying your valve we have created the RCVVALVES.COM Website which contains large images all on one page. Click on the image and you are taken to the Polar Bear, Inc. Web Store where you can view the price and purchase the product.

HOW DO I KNOW WHICH ONE TO BUY?

The first step is to physically look at the compressor and determine what brand is is. Some manufacturers, most notably Volkswagen, will use several brands of compressor for the same year, make, model and engine. These compressors will have the same footprint and will be interchangeable as complete units but the compressor components will not be. For example, two people might have identical vehicles in every way and one vehicle has a Sanden compressor and the other has a Denso compressor. The Denso can replace the Sanden and the Sanden can replace the Denso. They have the same footprint. HOWEVER, they each have different control valves. The valve for the Sanden is uniquely different from the valve for the Denso.

The next step is to look at the valve as it sits in the compressor and take careful note of how it is secured in place (snap ring or bolt). and what the exposed part of the valve and the connector looks like. A camera phone is often very useful for this purpose. Most of the time there is no need to remove the valve. A picture will usually suffice.

Now, compare your visual observations, or better yet, the images on your phone to the images on RCVVALVES.COM Website or our on site CONTROL VALVE PHOTO GALLERY. Both contain the same images. One significant feature will be the electrical connector, i.e.: Volkswagen and Audi use a unique connector often described as a VAG (Volkswagen Audi Group) connector. We do our best to exhibit these connectors in our images because if that is incorrect you can't use the valve.

After you identify the connector, the next thing to look at is what the top (exposed part) of the valve looks like, take note of any distinguishing features and compare them to our images. For example, the top of Sanden valve might have a small round post with a dimple in the center. Another Sanden valve might have a rectangular post with the shorter sides rounded while a Denso valve might have a "rib" across its diameter extending from the center of the connector. We have done our best to show these features in our images and while not 100% foolproof, they will help identify your valve with a reasonable degree of accuracy.

If you are still not certain of which valve you need feel free to call us and email us images of your valve. We will be happy to help you over the phone.

A worst case scenario might require you to remove the valve in order to properly identify it. Remembering to never attempt to remove the snap ring or bolt until you are certain all of the Freon is removed from the system. Failure to do this will cause it to shoot out of the compressor like a bullet and possibly cause serious bodily harm. Then use OUR CONTROL VALVE DIMENSIONAL CHART to narrow your selection by comparing chart dimensions to your valve. Take note that the length dimension is measured from the top of the valve that sits under the snap ring to the tip (bottom) of the valve (part inserted into the compressor).

Then, take note of the number and position of the orings on the valve and compare this information to our IMAGES. If all of these match you most likely have selected the correct valve. Again, to reiterate, FEEL FREE TO CALL US FOR ASSISTANCE. THAT IS WHAT WE ARE HERE FOR. 1800-365-3516

More to come in the near future

Hi, my name it's Adrian and ibefore I proceed to my order I want You to check for me wich is the RCV valve I need for my car. 2009 VW JETTA WAGON Tdi Highline, VIN # 3VWTL71K59M264271. Thank you. I am wondering if you do shipping to Canada ?